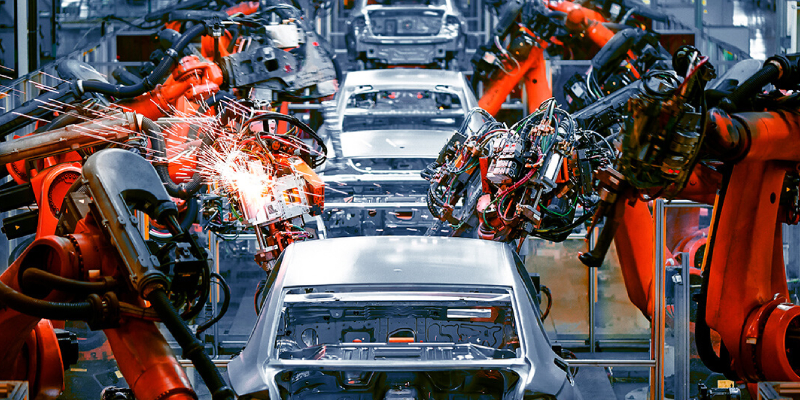

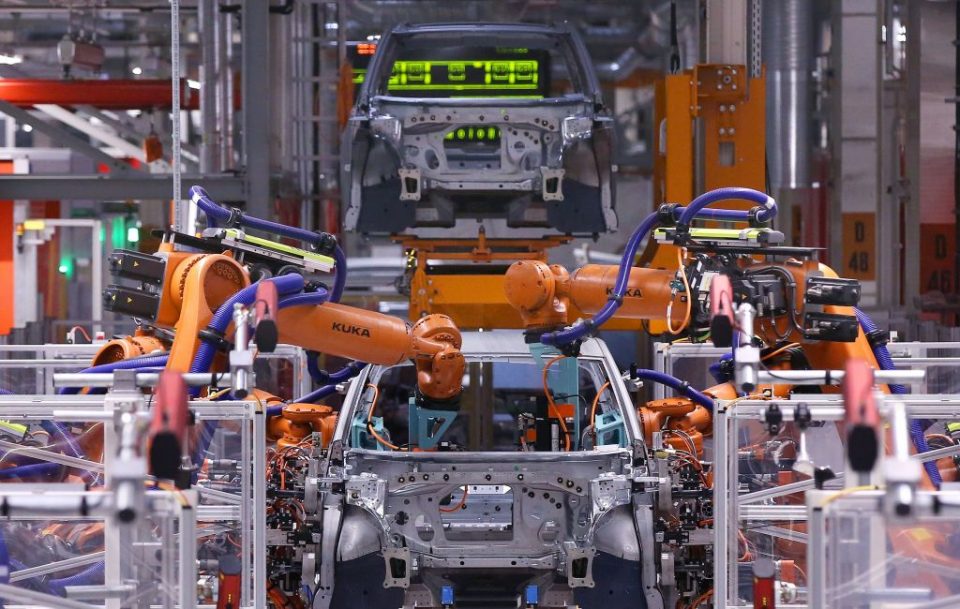

As the brave new world adapts to the integration of smart technologies and robotics, one industry has always been at the forefront when it comes to its use. That is the automotive industry, which has long reaped the benefits of robotic assistance.

Robotics is now so far advanced in the automotive sector that machines can check the closing of car doors and gauge if they ‘sound’ right or ‘feel’ correct. The industry has come a long way, but the big question is what can automation do for you? We look at the ways in which automation can help your automotive manufacturing business.

Robotics in the Automotive Industry

The automotive industry was one of the first to see the potential in robotics and automation. As early as 1961, General Motors were introducing prototype robots onto their assembly line for basic pick and place tasks. By the turn of the millennium, most car manufacturing plants had at least some degree of automation in place.

As car manufacturing plants begin to open up across South East Asia and India, your business needs to stay competitive in a global market. Automation can assist with that by lowering costs and increasing productivity in a number of ways.

Lower Operating Costs

Once the initial outlay has been spent on Robotics, you will see your operating costs being to fall sharply. A robot can easily do the same work as around 3 to 5 human workers. They will also minimize any product waste, also saving money.

In addition, they can work at times humans would increase labor costs, such as evenings and holidays. They do not tire and craftsmanship will remain high throughout the task.

To increase productivity, consider automating tasks not just on the work floor, but also in other areas. You can save money by automating wages and bill payments, as well as many HR tasks. This will relieve your staff of many burdensome tasks.

Increases Safety in the Workplace

The Occupational Safety and Health Act of 1970 was put in place to safeguard the well being of workers in the US. Using robotics in manufacturing promotes the application of the act by removing workers from hazardous situations.

This will also decrease the need for many forms of expensive safety equipment. It can also have a positive impact on business insurance premiums, due to a decreased chance of accidents happening in the workplace.

Increased Lead Times

Generally, the times it takes to get a product complete will be reduced with automation. By improving process control in automation, it will allow you to keep all elements on-site and take away the need for outsourcing or moving your manufacturing abroad. Products that you had previously been built elsewhere can now be manufactured in house.

Increased Production Output

With automation working for you 24 hours a day, it is no surprise that production can increase drastically. When introducing new products or methods, automation also cuts out training time and errors. This will allow you to bring in new processes and manufacturing without disruption to previous ones.

More Consistent Production

Humans, by their nature, are inconsistent. Even the best, highly trained workers will create variations and may make some errors. With automation, your product will contain much less variability than you would get with human workers.

With every action performed identically, you will get higher quality results. Customers will come to expect a standard in your brand that they recognize, trust, and return to.

Allow Workers to Be Utilised More Efficiently

One downside of automation is the often documented feelings of stress and anxiety workers have when a job is taken over by Automation. However, by managing this correctly workers can be redeployed so that benefit your company in other areas. This may mean a period of retraining for the individual.

Manage Workers Across Time Zones

Humans need to sleep, and changing time zones can be hard to manage tight schedules if you are a global business. Using automation, you can manage the tasks of your team across a range of different time zones. Decentralization should no longer be a barrier to your productivity.

This may mean you can manage outsourced tasks easily. You may also be able to check the efficiency of plants and workspaces across the globe, adapting them in real-time.

Considerations for Automated Automotive Manufacturing

When considering automation for your business, there are some points that must be taken into account. Luckily, they are few;

Using robots means using computers. You must ensure your staff is competently trained when operating the machines. Upgrading your internet security is also of the utmost importance to prevent hacking.

You must also be sure that any automation you purchase is compatible with your already existing systems. Any provider, such as Sanritsu, will be willing to discuss this with you.

Finally, calculate your return on investment. You should see yourself in profit very quickly. Your provider will also be able to discuss this.

Where Do We Go Next?

Collaboration between an automated and human workforce is a viable solution for your business. As technologies increase, it may be that both humans and robots can learn from each other in the automotive manufacturing sector. This can be used to your advantage.

If you are thinking of utilizing automation in your automotive process, then Sanritsu America can help. We have a track record of providing parts and equipment for the automated machine industry. Contact us to discuss your needs and the product most suited to maximizing your efficiency today!