Automation in manufacturing is growing rapidly. Even the US government is taking steps to encourage the development of advanced manufacturing. Is your facility taking full advantage of automation?

One way you can use automation to improve your manufacturing process is in quality control. Quality control is a critical step in automotive manufacturing, and automation can make a significant difference in your performance.

Inspection machines use computer visual technology to check parts for defects like contamination, dents, or scratches. They also check for compliance with part specifications.

Find out more about how inspection machines can give you a competitive edge.

Types of Automated Inspection Machines

Four basic categories of automated inspection systems are available. Choosing a system depends on your budget and your production needs.

Sensors Fitted to Existing Machines

Fitting sensors to existing machines on your production line is the most economical type of automated inspection. You don’t need to invest in new machinery. Machine vision cameras and precision laser measurement sensors are the most common sensors retrofitted onto existing machinery.

Sensors in a Controlled Environment

The second category of automated inspection systems uses the same sensors and technology as the first category. However, in this type of system, you put the sensors and other automated devices in a more controlled environment.

Installing sensors in an enclosure with light guarding gives you more consistent readings. You can connect the sensors to a machine like a pass-through conveyor that interacts with the inspection system. It can sort parts based on the pass/fail results of the inspection.

Turnkey Automated Inspection and Gauging Systems

A turnkey automated system has multiple cameras or lasers. It usually includes components like automatic feeder bowls and material handling as well as packing and labeling options.

Turnkey systems are custom made for a specific part or process. They are very accurate for the task they perform, but they have limited versatility.

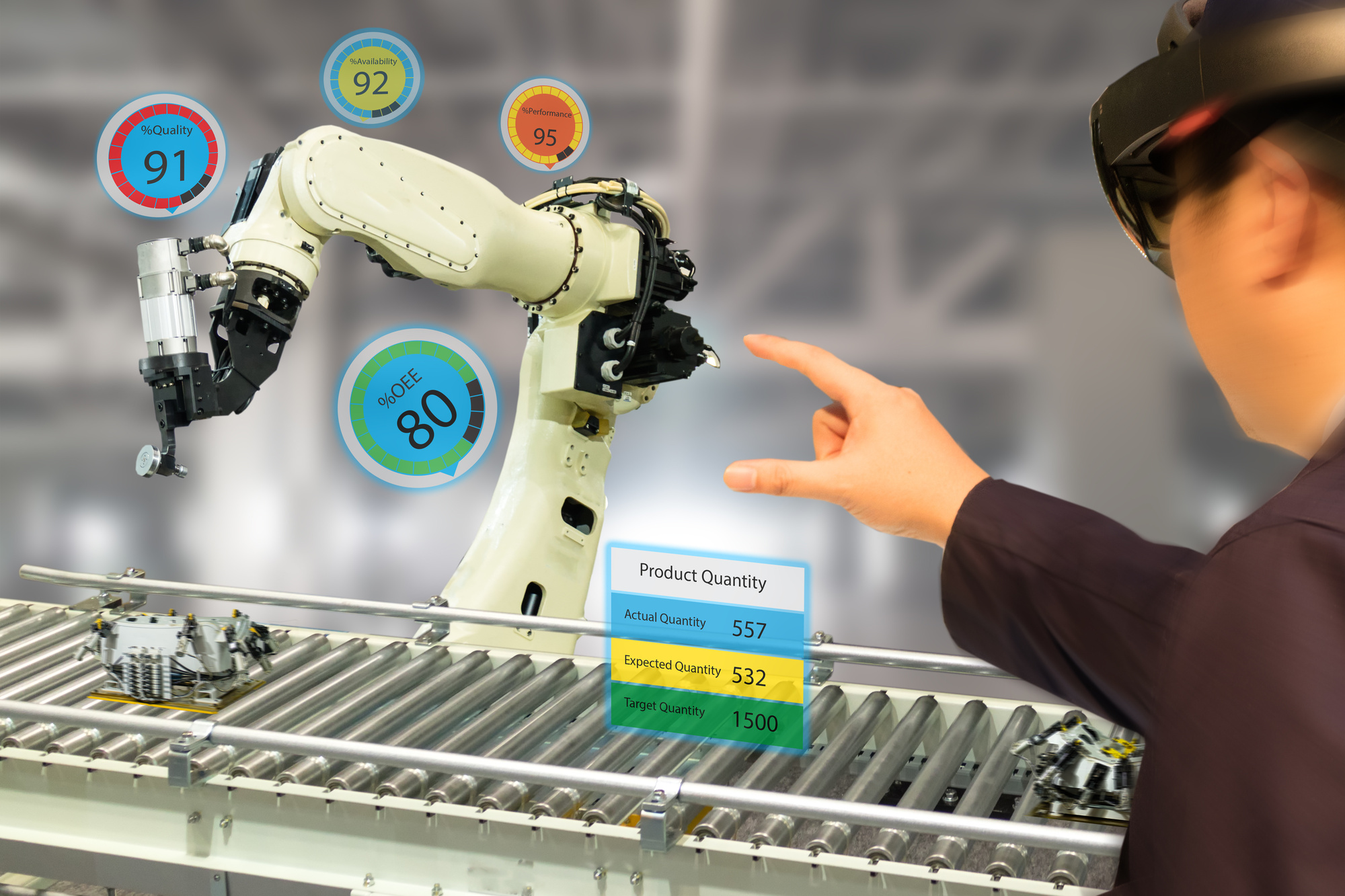

Programmable Robots

The final type of automated inspection system is the most flexible and versatile. Programmable robots take more comprehensive measurements by moving the part or the scanner.

These systems can handle more complex parts. They can perform a variety of tasks for different parts. You can program the robots to move to many different positions.

No matter which automated inspection system you choose, your manufacturing process will benefit.

1. Reduce Costs

Automated inspection machines reduce your costs in several ways. Each production run has less waste. You prevent substandard products from shipping, so you avoid the expense of re-shipping items.

Automated inspection machines can detect anomalies that aren’t yet defects. This data can alert your engineers, so they can fix the problem before defective parts are produced.

You lower your labor costs because you don’t need as many employees doing quality inspections.

2. Improve Quality

Inspection machines help you achieve accurate, fast, and repeatable production. You eliminate human error.

Manual inspection is labor-intensive. People who perform inspection tasks repeatedly can become distracted or tired. Defects can slip through the process.

Automation will give you the same output each time the machine inspects similar parts.

Quality improvement means you avoid losses from scrapped materials. Laser sensors can take micro-level measurements without touching the part. You avoid the possibility of accidental damage.

With consistently higher quality parts, you reduce your costs for problem resolution and support.

3. Increase Accuracy

Machine vision systems are extremely accurate. They can measure absolute dimensions. Inspection machines can identify complex visual properties that a human observer is likely to miss.

Compared to the human eye, machine vision has a higher optical resolution. Multispectral inspection machines have a wider visible spectrum, including infrared, UV, and x-rays. They can also do thermal imaging.

4. Raise Productivity

Inspection machines can work 24 hours a day. They only need short breaks for maintenance. You can program and monitor them remotely.

Automated inspection systems have a higher inspection speed than human inspectors. Some systems can take and process images in milliseconds or even microseconds. When you increase production, the inspection machines will keep pace.

5. Gain Efficiency

Automated inspection systems can catch errors faster and earlier in the process than manual inspection.

You can find problems and correct them before they impact production. You reduce scrap from failed parts. You also avoid production stoppages.

Automated inspection systems can examine every part. This is an improvement over manual audit-only inspections. You avoid losing time for containment and re-inspection.

6. Better Utilize Your Employees

Using automation for repetitive inspection tasks leaves your employees free for higher-level jobs. Manual inspection is often still necessary for situations like complex surfaces. The spontaneity of human intuition remains important in your inspection team.

Your manual inspection team will be able to do their jobs faster and easier when you add inspection machines. Your employees will be healthier and more efficient.

7. Expand Data Collection

Machine vision systems operate on digital images and data. You get data outputs in real-time that let you make more informed production decisions. This increases your manufacturing efficiency.

You can also use the data from your inspection machines to improve geometric dimensioning and tolerancing. You can more accurately define and control the allowable variants for each feature of a part.

Keeping digital records is simple. You can easily store and retrieve data. You have an advantage in terms of traceability and data analysis.

8. Grow Your Business

The advantages you get from automated inspection systems help you grow your business in a variety of ways. Improving efficiency and reducing costs give you more resources to use for expansion. You can more easily increase production to meet increased demand.

Higher quality products attract more buyers. You’ll have data on every feature of your products, which gives your clients the information they need to feel confident in their purchasing decisions.

Your customers will be more satisfied with their experience. They’ll know they don’t have to worry about quality issues, short shipments, or supply interruptions.

You’ll have data to demonstrate your commitment to continuous improvement. You can also show your customers that your manufacturing process is technologically up-to-date.

Getting Started with Inspection Machines

You need more than a supplier when you decide to implement an automated inspection system in your manufacturing facility. You need a true system integrator to bring all of your components together into a unified, solutions system with your inspection machines.

Sanritsu America has years of industry experience. We’ll provide you with the services you need to be successful. Contact us today to start designing your inspection solution.