Americans are spending up to 18 days in their cars over the course of a year. It’s no surprise that the same study says 45% of people cry when they have to let their cars go for one reason or another. 18 days a year we’re forming great experiences in our automobiles, and that amount of time is only going up.

How does manufacturing quality control play a role in this? Since we spend a lot of time in our cars, we want to make sure that they are not only high quality but safe to drive and be a passenger in.

Quality control directly relates to that safety and comfort. Want to know more about how quality control in manufacturing plays a part?

Keep reading to know how!

What Is Manufacturing Quality Control Today?

Quality control, or QC, is important in the automotive, machining, construction, and even writing industries. While the method of quality control is different in every industry, manufacturing deals with high volume and low tolerance for failure.

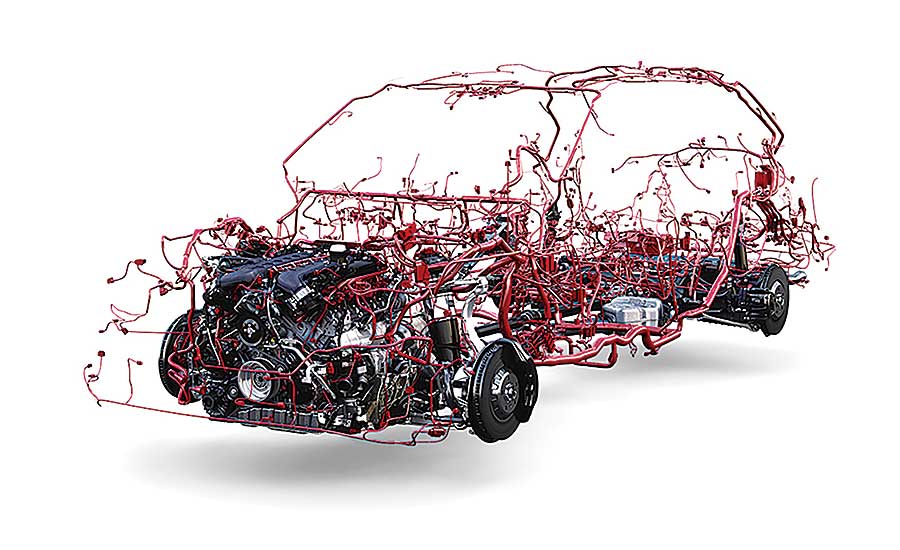

If a machine fails in the process of operation it isn’t just a breakdown, but possibly could even kill someone. With lives on the line, QC in the automotive industry is a large and involved process.

Starting from the beginning, things are engineered to different standards during the prototyping process. Once the prototype is built, then the fun really starts. Crash tests might be the only quality control process in the design of a car that most people are familiar with, but there are tons of other tests to check quality.

The car cabin is filled with smoke, and the seals of the car are tested. Another test for extreme temperatures (hot and cold) will determine the range of climates a car can handle reasonably. Yet another will determine how smooth a ride a car will have on rough or smooth terrain, and what the shocks can handle.

What happens when you don’t follow these processes? You can ask VW, as they took a shortcut and lost consumer trust by installing a “defeat device” in vehicles to beat emissions tests. Due to this, repairs for their cheat are costing the company billions of dollars.

What about manufacturing, though?

The Nuts and Bolts

Some trends in our digital age are going far beyond a simple caliper check and looking at a bill of lading for the materials.

Taking a sample from the raw material for chemical composition and durability testing is an ongoing and necessary practice. Things get mislabeled or switched around on accident in transit or in warehouses. It’s important to know the material you’re working with is the one you’re expecting to work with.

Thicknesses and size are another consideration for quality control.

Augmented Reality

Outside of simply checking material and dimensions, is checking the work you do with the materials. Augmented reality is a fairly new technology based on overlaying digital information in our real world. How is this possible?

If you’ve ever played a phone game like Pokémon, you might have an idea. Here are some ways AR (augmented reality) can improve manufacturing QC.

- Complex assembly

- Maintenance

- Expert support

Considering something like complex assembly, it’s really hard to become intimate with every iteration of a complex assembly project. Especially if you didn’t design it. Machines are becoming increasingly complex, which requires technicians to specialize further and further.

What It Means

Using AR, a technician can wear a digitally connected pair of lenses like glasses, which will give a heads-up-display like a manual, overlayed on top of the actual machinery in front of him. For example, an airplane engine assembly—something you wouldn’t want to go wrong.

In terms of maintenance, a technician can arrive on-site for a job and compare digital blueprints to what he sees in front of him. If he isn’t sure about a part, if it looks strange or anything else, he can compare the part to what is in his library for that machine.

If the technician needs further guidance outside of his specialty and realm of knowledge, it’s possible to get help from an expert on the machine directly.

In the past, the technician would have to arrange for a second call with an engineer, perhaps. Now the engineer can log in remotely and even “draw” on the heads-up-display or send a message to assist the technician. These innovations and more make things like AR a new reality in manufacturing quality control, as they hit more manufacturing floors.

These quality trends are here to stay and even grow exponentially.

Autonomy in Automotive Quality Control

With autonomous automobiles on the horizon, it means that there will be fewer operators to detect issues. A lot of people are looking forward to a future with electric cars that drive themselves. This is a great boon, but also requires greater control over quality in manufacturing and beyond.

Electric cars are a different breed altogether from an internal combustion vehicle, and that means that materials need to be handled and built to match. Efficiency and quality are the order of the day when talking about batteries, electric engines, and the devices that drive them.

Less moving parts, but more parts interacting and being part of the IoT, means that we can achieve an ongoing quality control environment, even when our automobiles have left the manufacturing and showroom floors.

Eventually, even you will be part of the quality control process.

Manufacturing Quality Control and You

Manufacturing quality control is a much bigger part of your life than you thought before, right? Next time you contribute to the 70 billion hours Americans spend in their cars in a year, remember that it’s been checked for safety and works as designed—and now you know how it will be achieved in the near future.

It’s a comforting thought.

Do you know what else is comforting? Sanritsu America Inc. spends considerable time, money, and energy making sure our products are up to spec and ready to go. We work with companies like FANUC Robotics to make sure not only the cars that automakers create are safe and in working order, but also the robots that make them.

Interested in learning more about how we can help you and your company? Contact us today and let’s talk about it.