In the manufacturing industry, it is important to have a competitive advantage. Yet, many manufacturers aren’t aware of what they should do to differentiate themselves. Setting yourself apart as a manufacturer doesn’t have to be hard. While there are many different things you can do, an area that you should focus on first is your costs. When it comes to costs, you want to find new and innovative ways to reduce them without cutting corners. One of the best ways to achieve this is through quality improvement.

It will not only save you money it will also save you time as well. If you are looking to learn how it will give you the competitive edge you’re looking for, we’ve created this article for you.

Here are 7 reasons why quality improvement cuts cost in manufacturing.

1. Reduction in Errors

The first reason why quality improvement can cut manufacturing costs is it can reduce your number of errors. Errors made by employees are bound to happen. When errors happen, it can reduce the quality of your process.

This can lead to an increase in cost. You can reduce employee errors by using employee training programs. Customized training programs can help you track the skill levels of employees and direct the help where it is needed.

Errors can also slow down your orders, which cuts down product quality. Quality improvement can help reduce errors in many ways. You want to think about customer quotes, pricing, products, and delivery instructions.

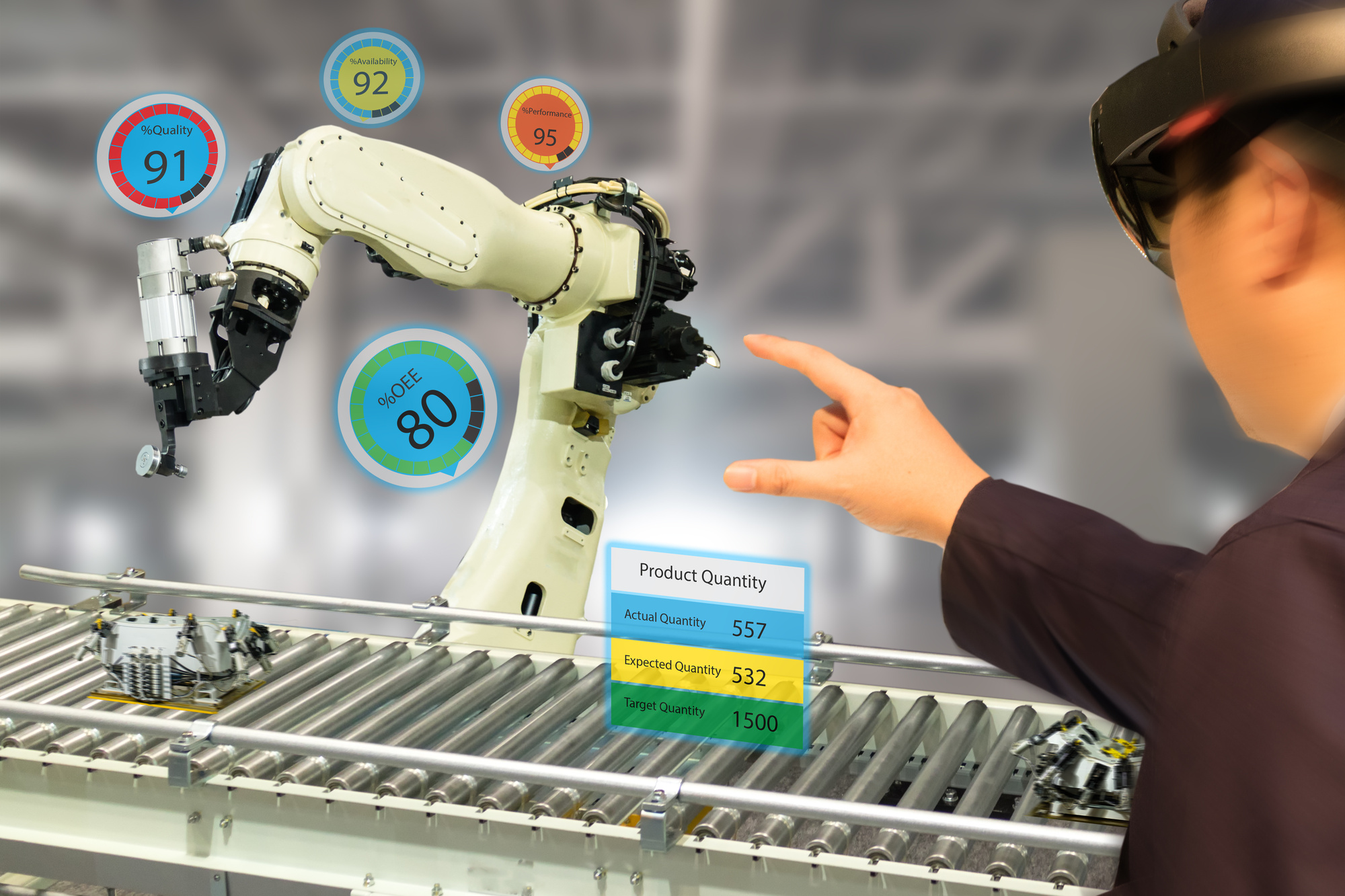

Another way it can reduce errors is with automation. Automation in industrial and manufacturing companies can reduce the number of employees needed. This also reduces the number of errors that can happen.

Overall, quality improvement provides you with real-time data to prevent errors before they happen.

2. It Helps Solve Problems

The next way it can cut costs is by using it to solve problems. You don’t want to think of quality improvement like a band-aid, that just fixes problems. It can also be used to discover the root cause of your quality issues. For instance, a machining center uncovers a problem with steps in the work process.

Using quality improvement can highlight the problem so you can find new ways to fix it. Improving work processes saves time and money.

3. Standardizes the Workflow

Another way quality improvement can cut costs is by helping you standardize the workflow. Work standardization is fundamental in creating an efficient production system. You want your work to be standardized in process, order, outcome, and timing.

What this means is the workflow is done the same way, every day. This includes the steps in the workflow and the time it takes to complete the desired outcome. If you don’t have standard procedures in which you operate from it could lead to extra expenses.

For example, you could automate pricing and customer quoting workflows. This can help improve your order cycle time, which enhances the quality of your manufacturing.

It will allow you to see areas of opportunity to standardize your workflow. It will also allow you to set the standards to ensure quality, which can help cut costs.

4. Allows You to View Things From the Customers Perspective

As a manufacturing company, your customer’s perspective is everything. You want to use quality improvement to get a better perspective on your customer’s satisfaction, as it can reduce costs.

For instance, chargebacks from a customer. That is something that costs you money. Quality improvement will allow you to understand how you can reduce the number of chargebacks. This will help cut the costs associated with them.

Quality improvement will also help you avoid losing customers or getting a bad reputation. The reason being, you will actively take measures to reduce those scenarios happening. Sales turnover in manufacturing is expensive.

Thus, using quality improvement can help you redefine your customer’s experience to reduce those costs.

5. Helps You Address Other Costs

One more reason quality improvement can help you cut costs is it allows you to understand how issues in quality increase your cost. Identifying systematic issues will allow you to find the best approach in all areas of the business, not just one.

Quality improvement will allow you to enhance everything from management to cross-departmental projects. This gives you a chance to fix the areas that aren’t up to standard. This will help you design manufacturing processes the are less wasteful, which will cut your costs.

6. Increases Production and Efficiency

Quality improvement can also cut costs because it increases production and efficiency. Taking proactive measures to ensure quality can increase your rate of production. An example of this would be using preventive maintenance to increase the output of your equipment.

Quality improvement will allow you to spot issues that are occurring. If your equipment is worn out it can increase your operating cost. Yet, with quality improvement measures in place, you will be able to replace worn equipment.

This will reduce your operating costs, thus, helping you cut costs.

7. Easier Manufacturing

The last reason why quality improvement can help you cut costs is with easier manufacturing. When you simplify your manufacturing process it reduces the chances of quality issues happening.

This can be done by using the proper tools for specific takes. Quality improvement will also help you reduce variations. You want better statistical control of the process, leading to easier manufacturing.

You Can Cut Costs by Ensuring Quality

Quality improvement shouldn’t be an afterthought when it comes to your manufacturing process. It is a great way to cut costs and improve your customer experience.

We’re here to help you achieve better outcomes for your manufacturing business. Whether it’s through automation, better tools, or assembly inspection we have you covered. Contact us today and take your quality improvement to the next level.